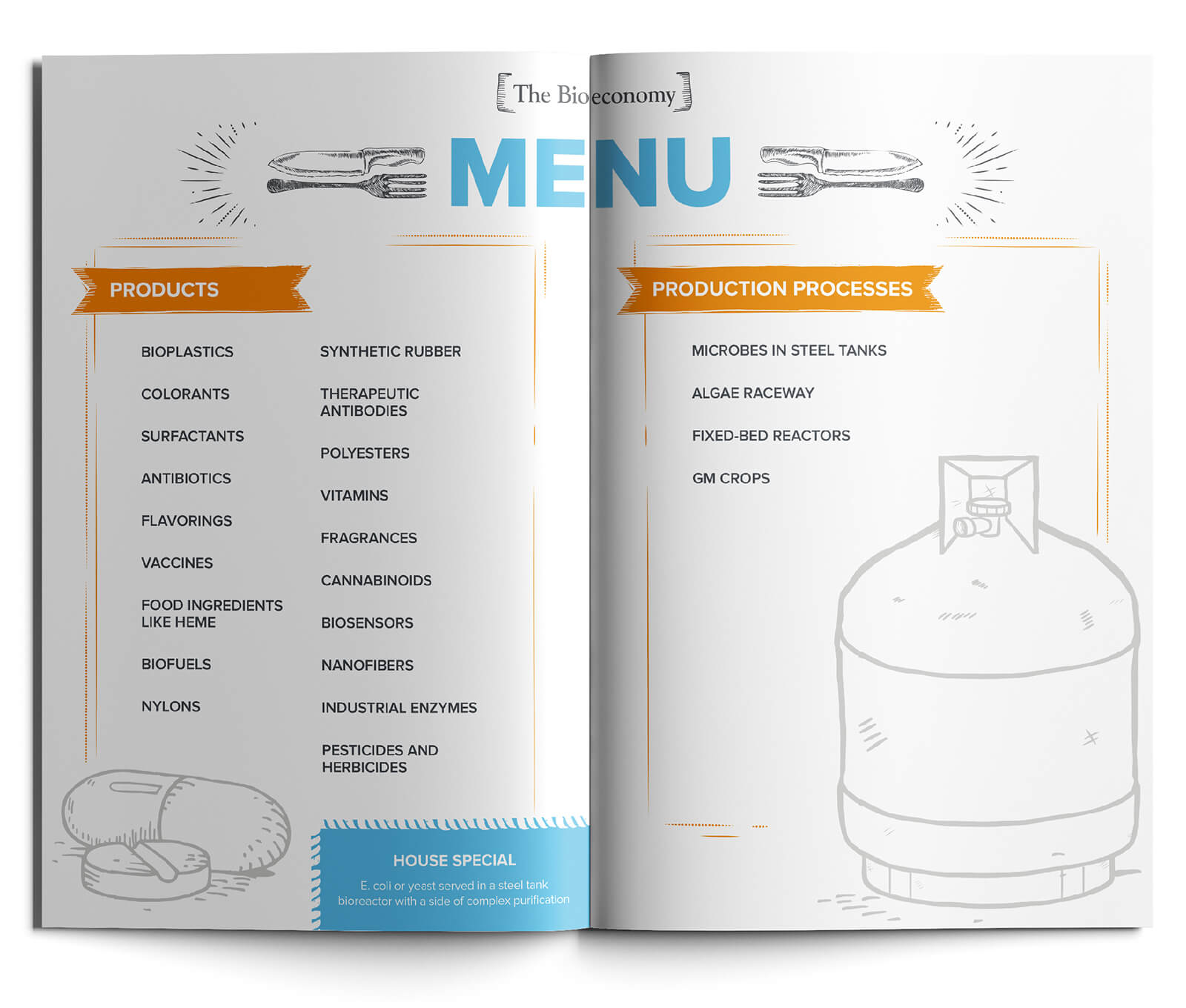

Many, many pieces have been written about the immense potential of synthetic biology to make manufacturing more sustainable, flexible, and cheaper. Synthetic biology presents the tantalizing opportunity for scientists and entrepreneurs to choose from a menu of products and a menu of production processes independently, so neither decision constrains the other. This could look like synthesizing leather using genetically modified microbes instead of being limited to its natural manufacturing process: growing an entire cow. Sounds pretty powerful, right?

So why haven’t we realized this dream of the “bio-based economy” yet? Why are we still harvesting products from natural sources despite the enormous progress in genetic engineering technologies? The real roadblock in our industry is that biomanufacturing using current production processes costs too much to be economically viable for many of the products attempted. The process menu has remained woefully short and the existing options are tricky and expensive. Expanding this side of the menu represents a huge opportunity to make biomanufactured products cheaper and thus far more likely to succeed in the market. We see several ways entrepreneurs can seize this opportunity and help realize the vision of a bio-based economy.

It’s time to think outside of the steel tank!

The vast majority of synthetic biology companies ultimately choose to use E. coli, yeast, or filamentous fungi in steel tank bioreactors as their manufacturing process. This choice seems sensible because these organisms are “domesticated” – meaning we know how to grow them, thanks to centuries of beer and winemaking tradition. There are established protocols and equipment for genetic engineering and we have trained generations of scientists to do so. But the inconvenient truth is that it’s expensive to run these bioreactors and scaling up often adds unexpected costs. Products also often need to undergo expensive purification processes. Lastly, performance issues plagued the first generation of synthetic biology companies, like the flagship company in the industry, Amyris. Their technology didn’t perform as expected at large scale, which they learned only after spending hundreds of millions on equipment and facilities for commercial manufacturing. Some companies have succeeded using these processes, but in these cases the product is either really expensive (e.g. insulin made by E. coli) or only used in tiny quantities as part of a final product (e.g. the biomanufactured heme made in yeast in the Impossible Burger).

The costs and scale-up challenges of these standard production processes are fairly consistent across product types using similar sized reactors, so there’s essentially a floor on the price of products for which it makes sense to use microbial fermentation and synthetic biology today. A good rule of thumb is that it is hard to make the economics work out for products with prices below $10/kg and to safely account for scale up issues and competition, prices would ideally be > $100/kg. However, much depends on the downstream processing and purification requirements for the final product. This limited price range severely restricts the variety of products that can be made using synthetic biology. Better production processes would help make the bioeconomy truly economical!

Three ways the product-process gap is an opportunity for entrepreneurs

Expanding the production process menu is a huge opportunity for scientists and entrepreneurs. We see three prime areas for innovation in process: first, expanding beyond these microbial workhorses; second, engineering new production hardware for growing and harvesting products from either new or established organisms; and third, devising clever methods for production-on-site that don’t require purification.

First off, many uncommon organisms may be ideal starting points for biological manufacturing because they naturally produce larger quantities of a compound related to the desired product (e.g. oleaginous yeast for oily products) or can be grown at scale without spending upfront to build a factory (e.g. insects, even crops). These may be harder to engineer at first, but the development of specialized tools can be a strong defensive intellectual property (IP) moat for a startup. Several key scientific advancements have unlocked the opportunity for domesticating new biomanufacturing hosts. CRISPR and related gene editing tools can work across phylogenetic kingdoms, making it easier than ever to perform genetic editing in new organisms. The rapid drop in DNA synthesis costs allows scientists more shots on goal when iterating on the DNA used to edit a new host. Many startups today, like C16, Chi Botanic, among several others, are innovating precisely on this axis by using non-standard organisms.

Second, bioreactor technology has not changed substantially in decades and we’ve seen a limited number of truly “disruptive” ideas in our production tech. The designs we have today are derivatives from the world of beer and wine. If we started from scratch, how would we build a system for growing biomass and harvesting a product from it? Some helpful methods exist, like tray-based fermentation for filamentous fungi or cell recycling, but most of these techniques are developed within product companies and are being built exclusively for their own product lines. With the growing interest in synthetic biology over the last decade, we believe there is an opportunity for a platform company to develop truly innovative production systems that can be partnered or sold to product companies.

Third, some products can be cleverly produced directly at their site of use. A perfect example of this approach is Bt-corn. Bt is shorthand for a family of toxic proteins produced by the bacteria Bacillus thuringiensis that poison insects when it accumulates in their stomachs. Agriculture companies could have transferred the gene encoding Bt into E. coli or yeast and produced and purified it at scale to spray on fields. Instead, inventors of Bt-corn had the smart idea to express the protein in the leaves of corn and soybean plants. Not only did they manufacture Bt in a way that doesn’t require additional harvesting, purification, and distribution steps, but they also choose a manufacturing method – in leaves – that places the product only where it is needed and not in the edible portion of the crop.

We hope to see more synthetic biologists zooming out to ask a broader question: what technologies can transform genetic information into low cost, purified molecular products? Surely steel tanks aren’t the last idea we’ll have. The limited innovation of the past is an opportunity for major advances today.